Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

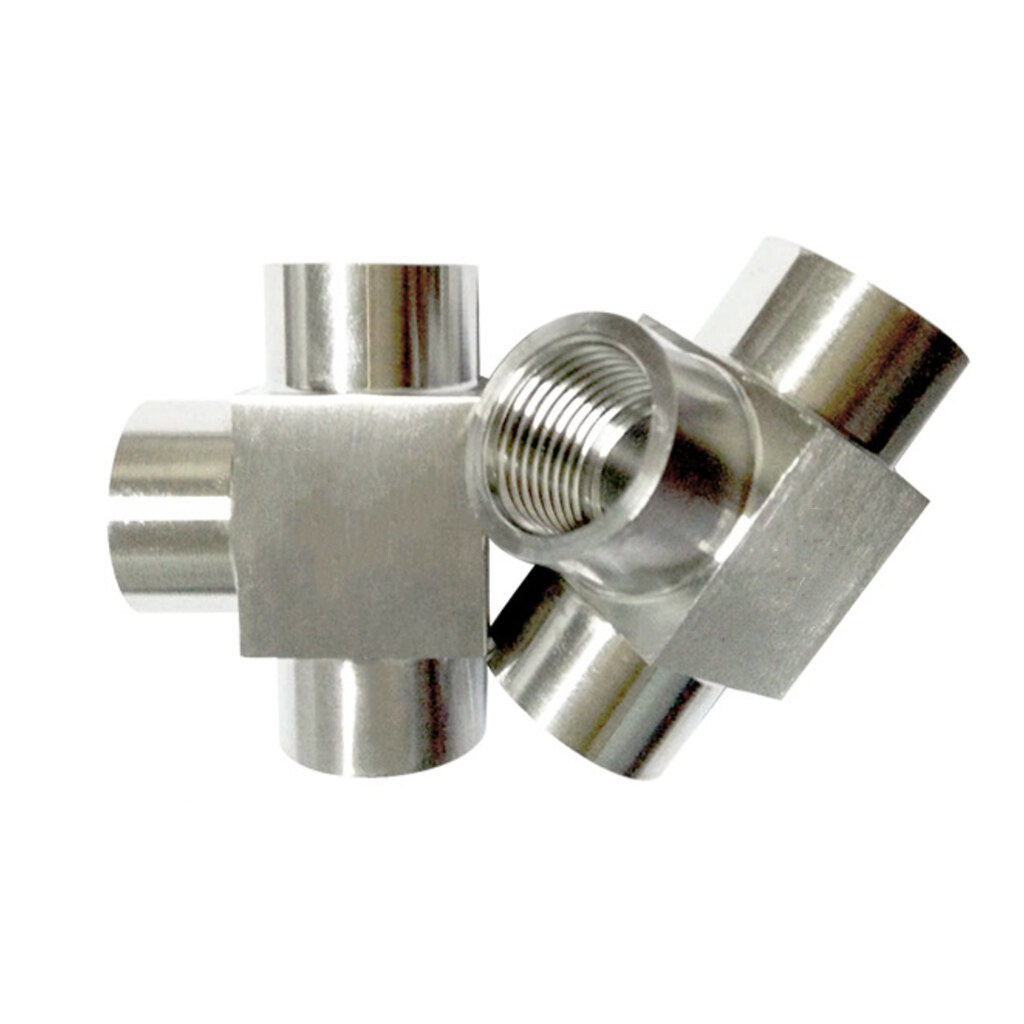

Check Valves for Air Suspension Lowrider Universal Air Compressor

A check valve, also referred to as a one-way valve, is one type of valve that only allows air to flow in one direction. Check valves are placed at the end of compressor leader lines and are useful for keeping your air tank separate from your bags. In order to remove the air tank while still maintaining air pressure in the air springs, many individuals install a check valve between their air tank and manifold. This also gives comfort in knowing that the air springs won't progressively lose inflated due to a tank leak.

Check Valves For Air Suspension Lowrider Universal Air Compressor

One sort of valve that only permits air to flow in one direction is a check valve, sometimes known as a one-way valve. Check valves are helpful for separating your air tank from your bags and can be found at the end of compressor leader lines. Many people may install a check valve between their air tank and manifold so that the air tank can be removed while still maintaining air pressure in the air springs. This also offers comfort in knowing that a tank leak won't result in the air springs gradually losing inflation over time.

The working principle of Check Valves For Air Suspension Lowrider Universal Air Compressor

Cracking force

A check valve must have a minimum upstream pressure (the difference in pressure between the inlet and exit) in order to open and allow media through. The check valve's "cracking pressure" is the lowest upstream pressure at which the valve opens. Make sure that the system's pressure can generate the cracking pressure of the selected check valve because the specific cracking pressure varies depending on the valve's design and size.

Closing

The check valve will close if the upstream pressure drops below the cracking pressure or if there is back pressure (flow attempting to transfer from the outlet to the inlet). The gate, ball, diaphragm, or disc on a check valve typically closes the valve by pressing against a seal. The process of shutting might be aided by gravity or a spring. The valve closes by gravity, a spring, and/or by utilizing backpressure as soon as the inlet pressure drops below the cracking pressure or there is backpressure.

Orientation for installation

Knowing the proper installation orientation is essential because one-way valves only allow flow in one direction. Usually, a flow direction indicator is an arrow on the valve casing. If there isn't an arrow, make sure the valve is installed in the proper flow direction by looking at it. Media won't be able to flow through the system if the valve is fitted backward, and the consequent pressure buildup may result in damage.

Check valves that are both ordinarily open and closed

A typically open check valve permits free passage of the medium but stops it in the event of backflow. Until the cracking pressure increases, a usually closed check valve stops media from passing through it; at that time, the valve opens.